Projects

See first-hand what we can deliver

With AIC as your partner, you can expect to receive exceptional service on any traditional automation or system integration project you pursue. In addition to routine project capabilities, AIC has developed extensive experience with particular project challenges. Below are a few examples where AIC has developed extensive experience overcoming these challenges:

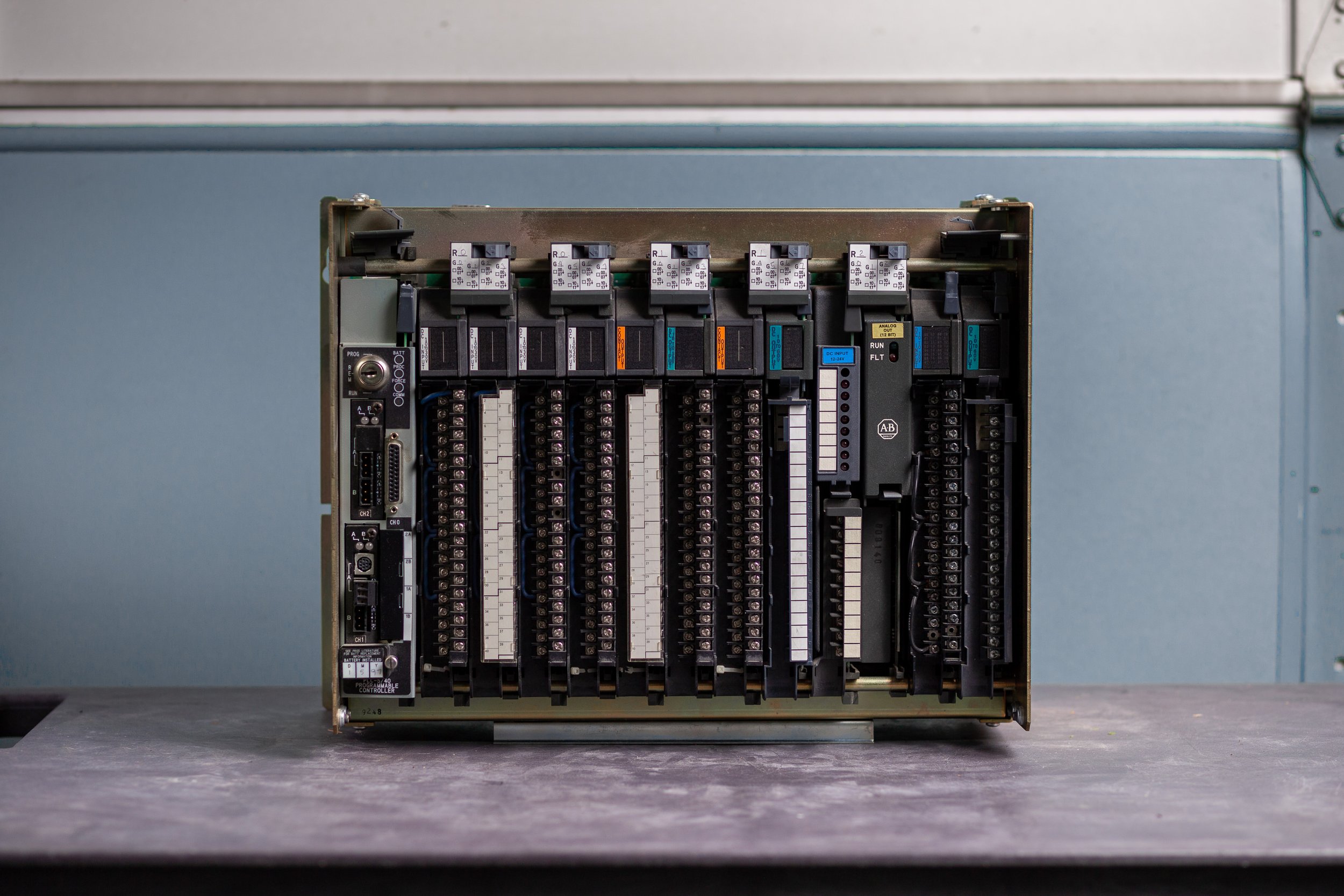

Platform to Platform Conversions

Several AIC customers have engaged us to assist them in upgrading older legacy systems to up-to-date technology.

These projects can present significant operational and planning challenges since functioning systems must have existing hardware taken out of service, removed, and all programming and configuration settings converted to new technology.

Then new hardware, programming, and configuration must be installed, tested, and commissioned/validated. There are several critical activities in a conversion process which typically must be completed during a limited, scheduled outage. The normal time for debugging and start-up is drastically reduced on these projects because the plant needs a vertical start-up at the end of the scheduled outage.

AIC recently converted two legacy manufacturing systems to modern technology. Working in partnership with our customer, we obtained complete copies of the existing system programming and configuration settings and made the conversion to the new system in our shop. This enabled us to perform functionality testing and debugging prior to the scheduled outage. During the outage, the existing hardware was quickly removed, and the new system was installed. Programming and development time that would have normally been incurred during the outage was used to make the final tests and perform the start up. We have replicated this process in several projects with great success.

Simultaneous System and Validation Test Design

AIC performs a significant amount of automation work within highly regulated environments. When we plan a project, we are focused on the fully functioning system being available to produce product on the target start date.

Some of the most challenging project deliverables such as planning, testing, and documentation happen after the project is ready to operate. Many projects that are ready for testing will remain idle while tests and commissioning/validation documentation is being prepared.

AIC recently designed a new batching process control system for a regulated customer. The project included design, programming, system documentation, startup, and commissioning/validation.

To avoid start-up delays after installation, AIC’s validation assistant worked as part of the design team so that testing plans and documentation could be developed simultaneously as the system was being designed. This enabled AIC to quickly move into the testing phase of the project with a testing team that was very knowledgeable of the design and objectives of the tests. Approaching validated projects this way enables us to quickly document validation testing and close the project.